Our BX-Series

Precision stages

Motorized Precision Stage

- Repeatability: < 1µm

- Travel Stroke: 20 - 300 mm

- Axis Width: 50 / 60 / 80 mm

- Closed and Open Loop

- Plug & Play

< 1µm

20 - 300 mm

Stepper Motor

up to 50 mm/s

Plug & Play

Introduction

Specs

Configurations

Control

Order Guide

Accessories

Download

Why linear positioning stages?

Linear positioning stages offer high precision, repeatability, and flexibility, making them indispensable tools in industries where precise motion control is essential for achieving high-quality results.

Advantages over manual positioning stages

Unlike manual stages, which rely on human operators for adjustment, motorized stages are controlled electronically, allowing for precise positioning with minimal error.

Motorized stages enable automation that not only increases efficiency, but also increases repeatability as motorized stages can reliably return to specific positions, ensuring consistent results over time. They can be easily programmed to follow predefined paths or sequences of movements, allowing for complex motion profiles that would be challenging or impossible to achieve manually.

Key features and benefits of the BX-Series

The BX positioning stages are characterized by its monoblock design. The guides and the body are made of one stainless steel profile. The combination with gothic arch ball guiding results in extremely high precision with very high thermal stability and smooth running. Preloaded angular ball bearings and the C3 ball screw enable backlash-free positioning with a repeatability of less than 1 μm.

Available motor options

Plug & Play Closed Loop Controller

- Internal or external controller

- High resolution (16.000 ppr)

- No hunting

- RS485 / USB, Ethernet or EtherCAT Interface

- Comes with Windows Software

- Programmable by LabView, C++, Python, etc.

- High torque, continuous motion

Integrated Controller

- RS-485 / USB

External Controller

- RS-485 / USB, Ethernet, EtherCAT

- Positioning table

Open Loop Nanotec© Stepper Motor

- Integrable to any 2 phase stepper motor controller

- High quality, long life time

- High holding torque

- High precision accuracy

Available Interfaces

- RS-485 / USB

- Ethernet

- EtherCAT

- EtherNet/IP*

- PROFINET*

- PROFIBUS*

- DeviceNet*

* using FASTECH Ezi-MotionGate

Professional Industrial Connector

- Harting ix industrial connector

- Robust and minituarized connector

- Stable and reliable

- Easy Plug & Play

- Shielded cable

- Adapters available

Technical specifications

| BXS | BXN | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 60 | 80 | 50 | 60 | 80 | |||

| Mechanical | Travel Stroke | [mm] | 20-30 | 20-50 | 20-50 | 50-250 | 75-300 | 75-300 |

| Moving Platform DImension | [mm] | 50x50 | 60x60* | 80x80** | 50x50 | 60x60 | 80x80 | |

| Screw Type | Ball screw 1 mm pitch | Ball screw 1 mm pitch / 2 mm pitch | ||||||

| Guiding System | Linear ball cage guiding | Circular linear ball guiding | ||||||

| Resolution Full Step | [µm] | 5 | 5 / 10 | |||||

| Weight | [kg] | 0,57 - 0,72 | 0,75 - 1,11 | 1,15 - 1,35 | 1,24 - 1,76 | 1,3 - 2,6 | 1,84 - 3,2 | |

| Maximum Load Horizontal | [kg] | 6 | 7 | 8 | 10 | 14 | 18 | |

| Maximum Load Vertical | [kg] | 4 | 5 | 5 | 7 | 9 | 11 | |

| Max. Torque Θx | [Nm] | 1,82 | 2,35 | 3 | 2,5 | 3,33 | 4 | |

| Max. Torque Θx, Θz | [Nm] | 1,67 | 2,31 | 2,86 | 1,88 | 2,5 | 3 | |

| Accuracy | Pitch | [µrad] | 20" | 20" | 20" | 20" | 20" | 20" |

| Yaw | [µrad] | 15" | 15" | 15" | 15" | 15" | 15" | |

| Roll | [µrad] | N/A | N/A | N/A | N/A | N/A | N/A | |

| Parallelism | [µm] | 15 | 20 | 20 | 20 | 20 | 20 | |

| Dynamic Straighthness | [µm] | 2 | 2 | 2 | 2 / 6 | 2 / 6 | 2 / 6 | |

| Dynamic Parallelism | [µm] | 10 | 10 | 10 | 10 / 15 | 10 / 15 | 10 / 15 | |

| Electrical | Connector Type | HARTING ix Industrial® | ||||||

| Number of Limit Switches | 3pcs. Photo Electric NPN 24V | |||||||

| Material | xy-Mounting | M3x5 | M4x5 | M4x5 | M4x5 | M4x5 | M4x5 | |

| z-Mounting | Angle bracket (for Z-type axis) | |||||||

| Body Material (finish) | Stainless Steel / Electroless Nickel Plating | |||||||

| Connector Housing Material (finish) | Anodized Aluminum | |||||||

| Environment Pressure | [mbar] | N/A | ||||||

| Environment Temperature | [°C] | 50 (with controller) / 70 (without controller) | ||||||

| Environment Humidity | [%] | angle bracket (for Z-type axis) | ||||||

| Protection Level | [IP] | - | ||||||

| Declaration of Complience | RoHs / REACH | |||||||

| Performance | Max Velocity (100%) | [mm/s] | 20 | 20 | 20 | 20 / 40 | 20 / 40 | 20 / 40 |

| Max Acceleration (100%) | [mm/s²] | 100 | 100 | 100 | 100 | 100 | 100 | |

| Absolute Accuracy | [µm] | 5 | 5 | 5 | 5 - 25 | 5 - 25 | 5 - 25 | |

| Repeatability Bi-Directional | [µm] | ± 0,5 ± 0,25 with Ezi-SERVO | ||||||

| * Table Size is 60mm x 80mm for a Travel Stroke of 50mm ** Table Size is 80mm x 100mm for Travel Stroke of 50mm | ||||||||

| Internal | External | |||||||

|---|---|---|---|---|---|---|---|---|

| Controller | Input Voltage | [VDC] | 24 | |||||

| Current Consumption | [mA] | max. 500 (except motor current) | ||||||

| Resolution | [ppr] | 16.000 | 10.000 | |||||

| Resolution | [r/min] | 3.000 (at up to 10.000ppr) | ||||||

| Communication Interface | RS-485 / Ethernet / EtherCAT | |||||||

| GUI* | Windows 7 and up | |||||||

| Library* | Windows & Linux | |||||||

| * except EtherCAT | ||||||||

Technical drawing And Dimensions – BXS

| Unit: [mm] | ||||||

| Travel Stroke | B | L1 | L (CI) | L (CE) | L (O) | |

|---|---|---|---|---|---|---|

| BXS50 | 20 | 50 | 88,5 | 156,5 | 152,1 | 142 |

| 30 | 50 | 97 | 165 | 160,6 | 150,5 | |

| BXS60 | 20 | 60 | 86,5 | 154,5 | 150,1 | 140 |

| 30 | 60 | 96,5 | 164,5 | 160,1 | 150 | |

| 50* | 60 | 131,5 | 199,5 | 195,1 | 185 | |

| BXS80 | 20 | 80 | 106,5 | 174,5 | 170,1 | 160 |

| 30 | 80 | 116,5 | 184,5 | 180,1 | 170 | |

| 50** | 80 | 131,5 | 199,5 | 195,1 | 185 | |

| * Table Size is 60mm x 80mm for a Travel Stroke of 50mm ** Table Size is 80mm x 100mm for Travel Stroke of 50mm | ||||||

Technical drawing And Dimensions – BXN

| Unit: [mm] | ||||||

| Travel Stroke | B | L1 | L (CI) | L (CE) | L (O) | |

|---|---|---|---|---|---|---|

| BXN50 / BXN60 / BXN80 | 50* | 50 / 60 / 80 | 183 | 191+B | 186,6+B | 176,5+B |

| 75 | 50 / 60 / 80 | 208 | 216+B | 211,6+B | 201,5+B | |

| 100 | 50 / 60 / 80 | 233 | 241+B | 236,6+B | 226,5+B | |

| 150 | 50 / 60 / 80 | 283 | 291+B | 286,6+B | 276,5+B | |

| 200 | 50 / 60 / 80 | 333 | 341+B | 336,6+B | 326,5+B | |

| 250** | 60 / 80 | 383 | 391+B | 386,6+B | 376,5+B | |

| 300** | 60 / 80 | 433 | 441+B | 436,6+B | 426,5+B | |

| * not available for BXN60 and BXN80 ** not available for BXN50 | ||||||

Closed Loop Configuration Internal Controller, open cable end

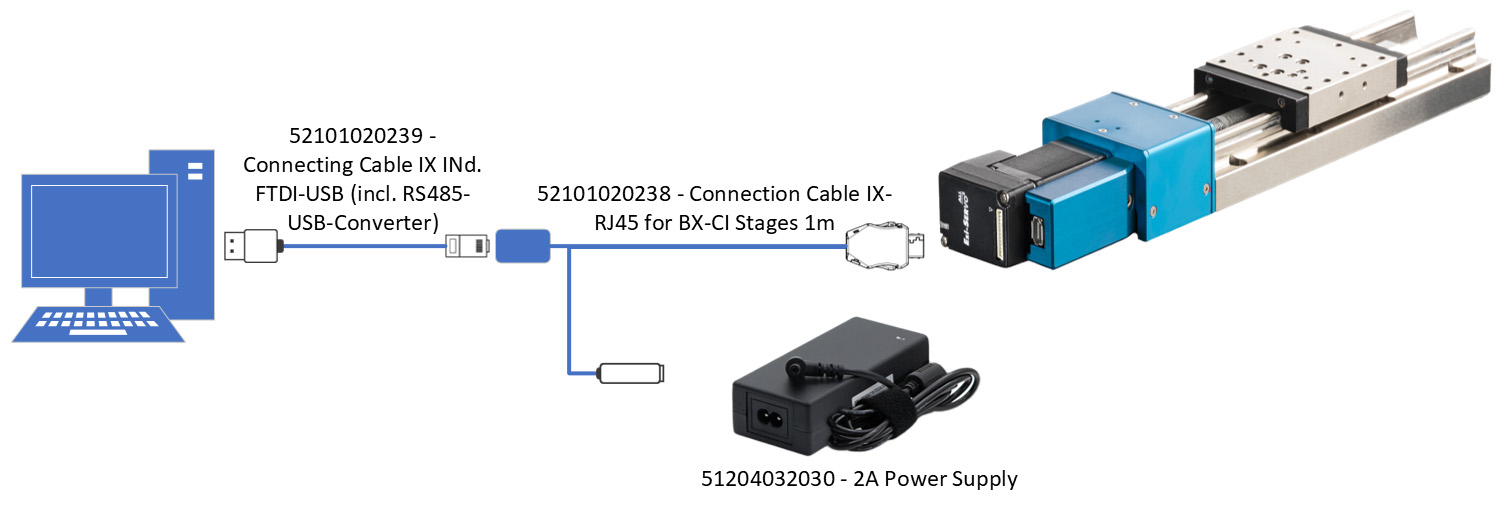

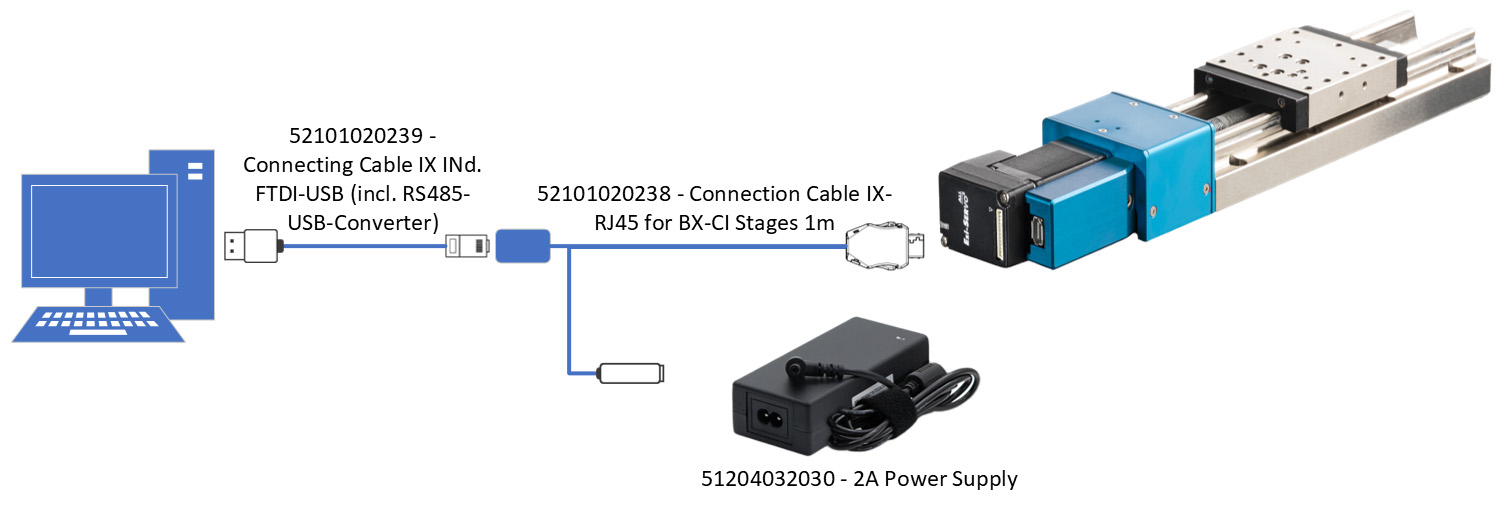

Closed Loop Configuration Internal controller, USB

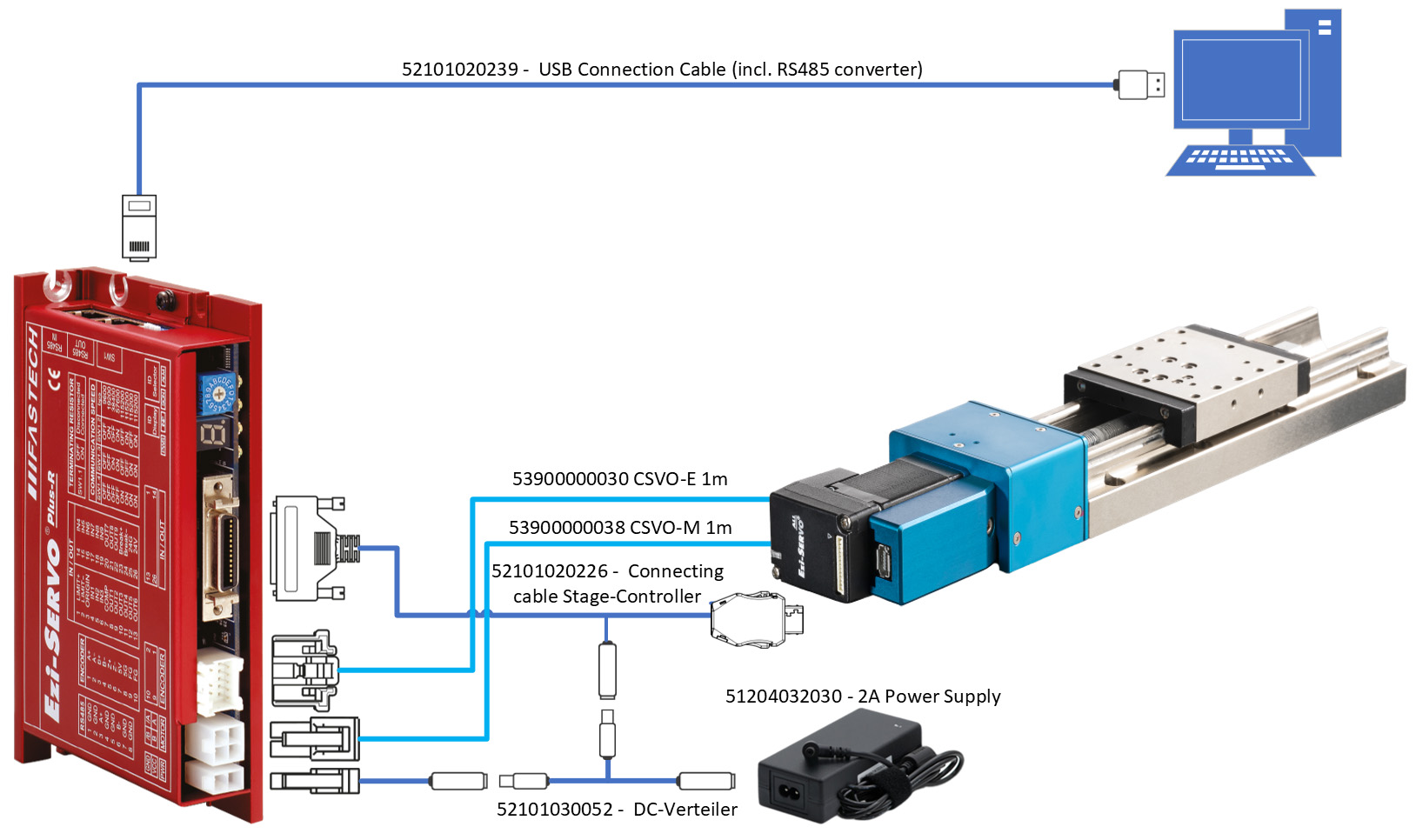

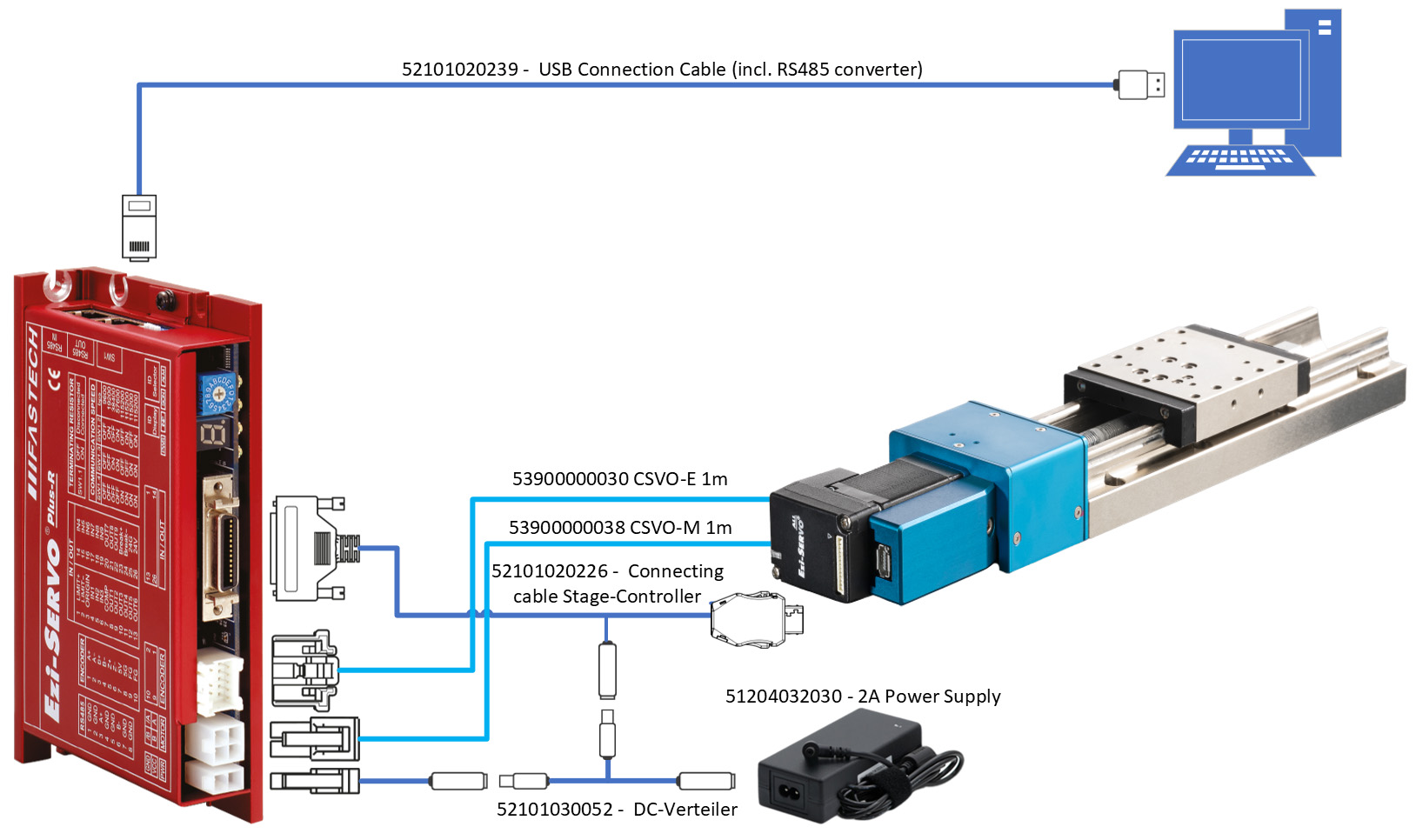

Closed Loop Configuration External controller

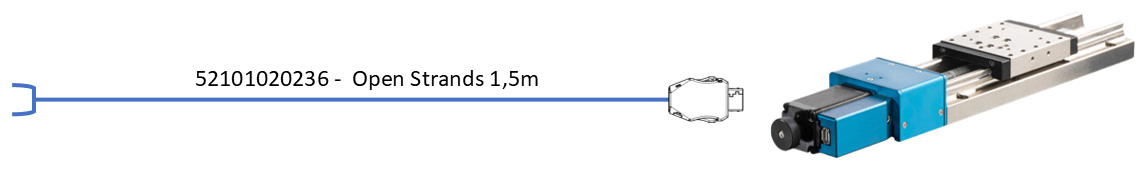

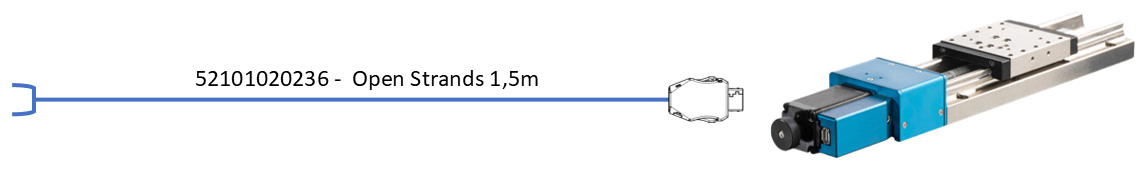

Open Loop Coniguration Without controller, open cable end

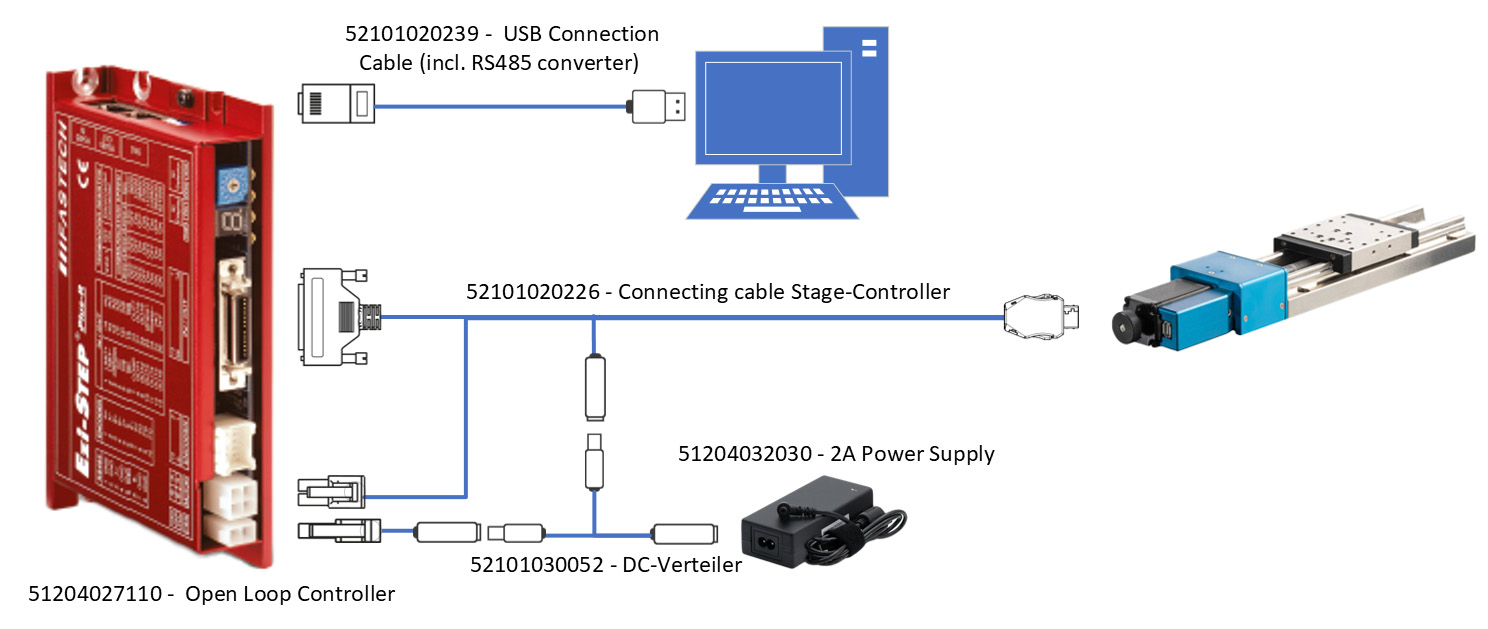

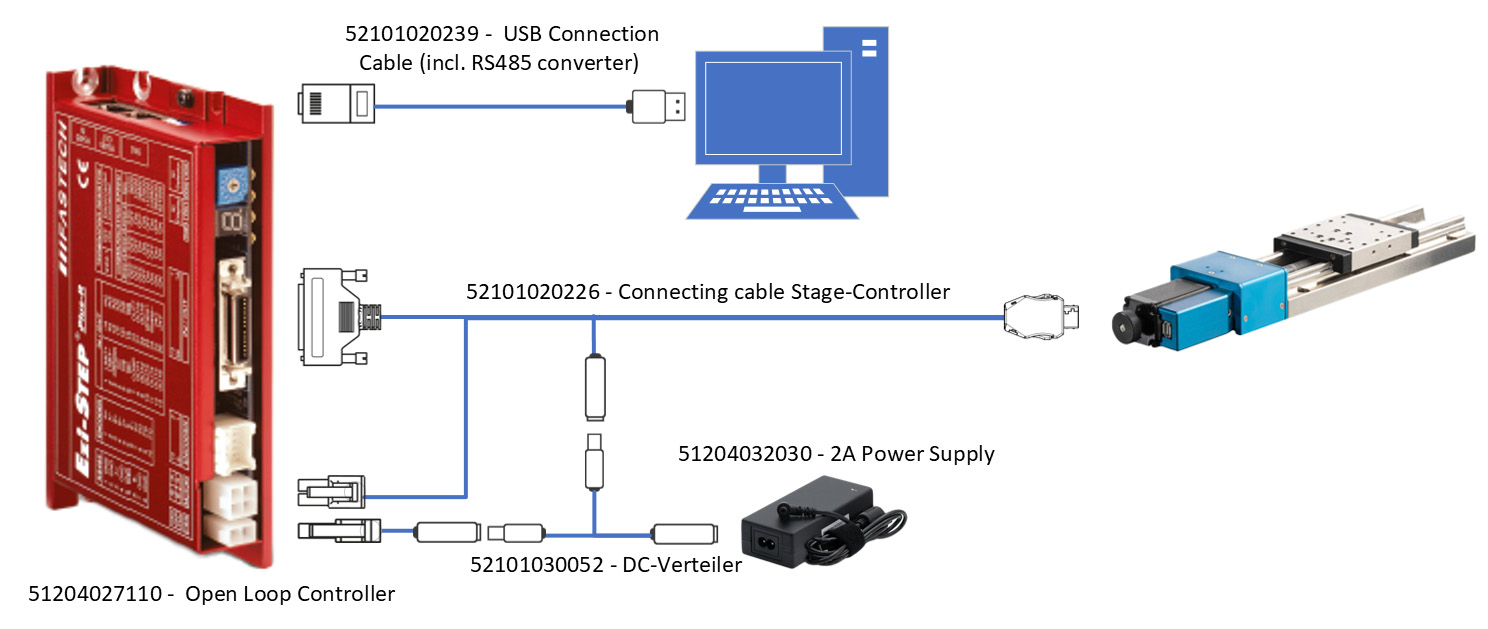

Open Loop Coniguration External controller

Available Interfaces

- RS-485 / USB

Controllable via Ezi-MOTION Plus-R and self-developed software

Programmable via supplied DLL (C++, C#, LabView, Python, etc.) - Ethernet*

Controllable via Ezi-MOTION Plus-E and self-developed software

Programmable via supplied DLL (C++, C#, LabView, Python, etc.)

* Not to be confused with EtherNet/IP - EtherCAT

CiA402 Drive Profile Support

Ezi-MOTION Plus-R

- Connect the stepper motor controller to your PC.

- Select the COM port via which your controller can be addressed on the computer.

This varies from computer to computer, but retains the value after setup. Selecting the wrong port has no effect. - Select the controller you want to work with.

Ezi-MOTION Plus-E

Recommendation: Use a second network interface on your PC to communicate with the stepper motor controller.

- Connect the stepper motor controller to your PC.

- Enter the IP of the controller. This is displayed on the stepper motor controller via LEDs.

- Select the controller you want to work with.

Ezi-MOTION - GUI

The software offers you extensive options for configuring and controlling your stepper motor controller. Parameters can be adjusted, such as pulses per revolution, switching the sensors from high active to low active and configuring the input and output signals. The creation of position tables for stand-alone operation and direct control via the software can be conveniently carried out here.

Detailed information on using the interface can be found in the FASTECH manual.

Order Guide

| BXN | 50 | 200 | - | C | E | - | EC | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

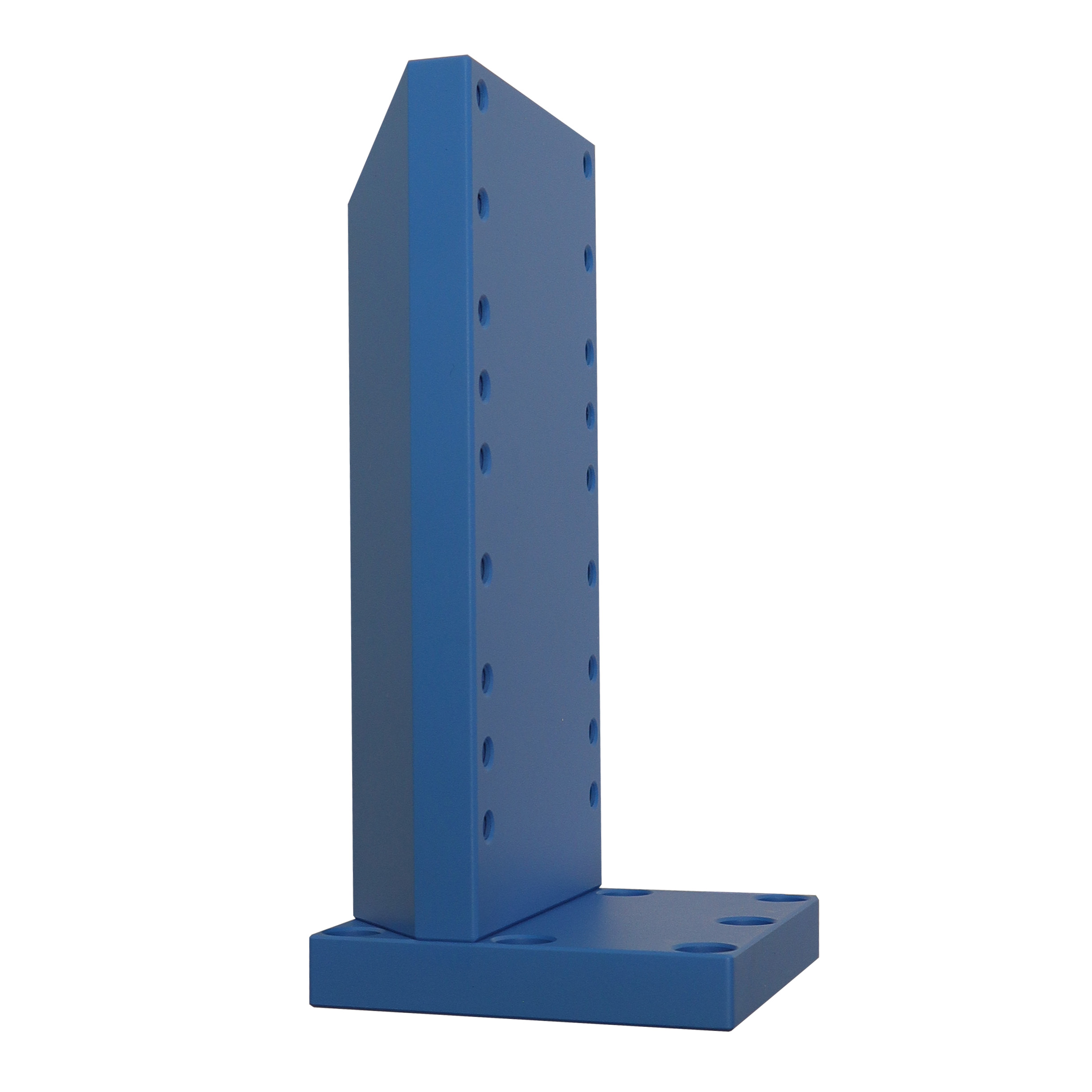

Angle Brackets

The angle bracket allows two positioning tables to be mounted at right angles to each other, enabling flexible and precise positioning not only in the XY plane, but also in the Z direction. This robust angle adapter is made of either blue or black anodized aluminum and is equipped with several fastening points that ensure a stable and secure connection between the positioning tables.

Base Plates

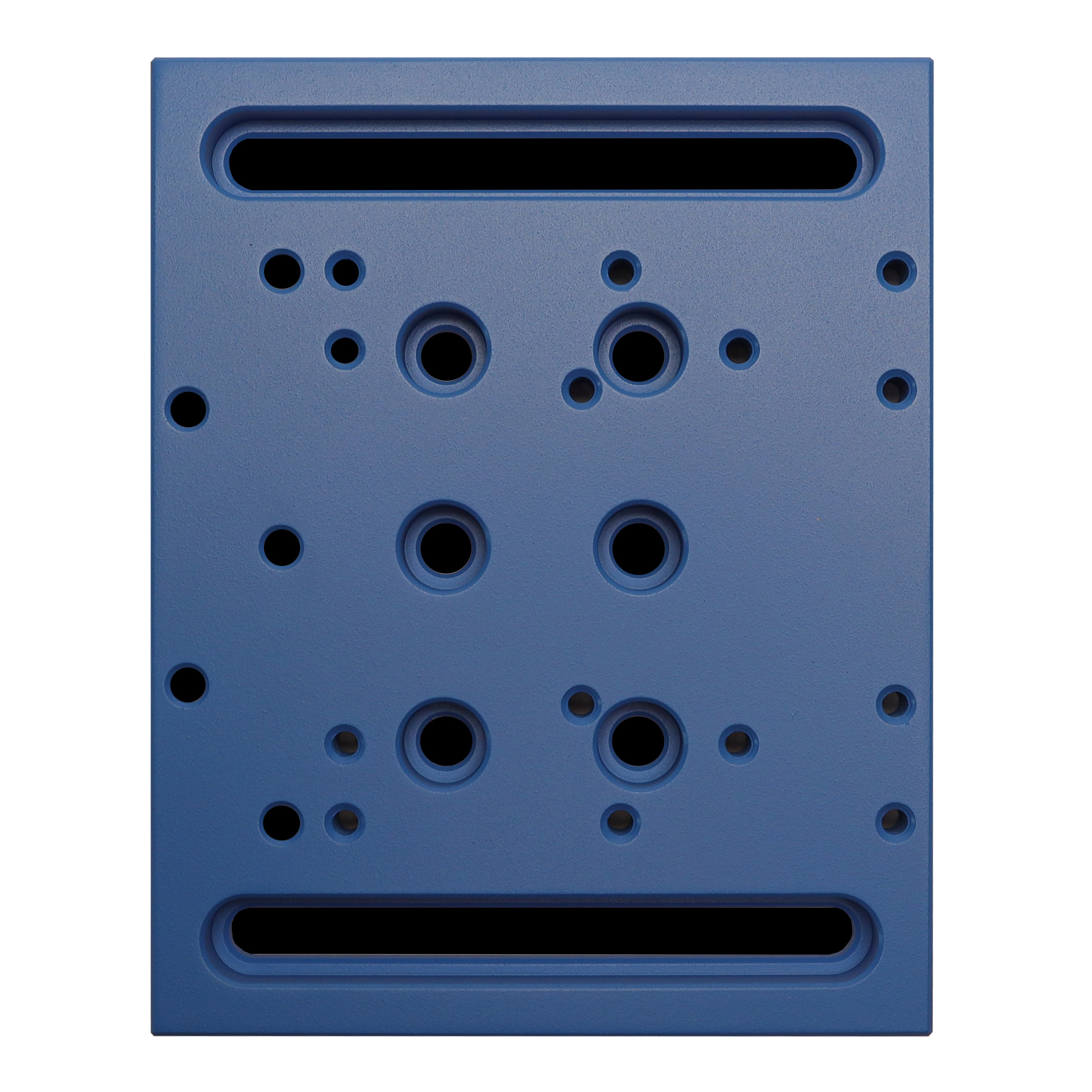

Using the base plates, the motorized stages of the BX and CX series can be mounted on breadboards, or for XY mounting on optical tables from other manufacturers with different hole patterns. can be attached. These are made of aluminium and are available with a blue anodized finish. By the base plates, you can customize and expand your existing system to meet your specific requirements. expand your existing system to meet your specific requirements.

Ezi-MOTIONGATE

With Ezi-MotionGate from FASTECH, you have the option of integrating our motorized positioning stages from the RS-485 series into your existing industrial network. Supported protocols are PROFINET, EtherNet/IP, PROFIBUS DPV1 and DeviceNet. There is already a native solution with an external controller for connecting to an EtherCAT network

Wiring

Depending on the configuration, different cabling is required to control the motorized positioning stages. You can view the possible configurations under the “Configurations” tab.

Power Supply

We will be happy to supply you with the appropriate power supply unit for your motorized positioning table, if required.

Available Variants

BXS50

BXS60

BXS80

BXN50

BXN60

BXN80

BXS5020-O

Table Size: 50x50 mmTravel Stroke: 20mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS5020-CI

Table Size: 50x50 mmTravel Stroke: 20mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS5020-CE

Table Size: 50x50 mmTravel Stroke: 20mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS5020-CE-EC

Table Size: 50x50 mmTravel Stroke: 20mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS5020-CE-EN

Table Size: 50x50 mmTravel Stroke: 20mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS5030-O

Table Size: 50x50 mmTravel Stroke: 30mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS5030-CI

Table Size: 50x50 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS5030-CE

Table Size: 50x50 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS5030-CE-EC

Table Size: 50x50 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS5030-CE-EN

Table Size: 50x50 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS6020-O

Table Size: 60x60 mmTravel Stroke: 20 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS6020-CI

Table Size: 60x60 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS6020-CE

Table Size: 60x60 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS6020-CE-EC

Table Size: 60x60 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS6020-CE-EN

Table Size: 60x60 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS6030-O

Table Size: 60x60 mmTravel Stroke: 30 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS6030-CI

Table Size: 60x60 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS6030-CE

Table Size: 60x60 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS6030-CE-EC

Table Size: 60x60 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS6030-CE-EN

Table Size: 60x60 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS6050-O

Table Size: 60x80 mmTravel Stroke: 50 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS6050-CI

Table Size: 60x80 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS6050-CE

Table Size: 60x80 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS6050-CE-EC

Table Size: 60x80 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS6050-CE-EN

Table Size: 60x80 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS8020-O

Table Size: 80x80 mmTravel Stroke: 20 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS8020-CI

Table Size: 80x80 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS8020-CE

Table Size: 80x80 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS8020-CE-EC

Table Size: 80x80 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS8020-CE-EN

Table Size: 80x80 mmTravel Stroke: 20 mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS8030-O

Table Size: 80x80 mmTravel Stroke: 30 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS8030-CI

Table Size: 80x80 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS8030-CE

Table Size: 80x80 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS8030-CE-EC

Table Size: 80x80 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS8030-CE-EN

Table Size: 80x80 mmTravel Stroke: 30mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXS8050-O

Table Size: 80x100 mmTravel Stroke: 50 mmGuiding: Linear ball cageOpen LoopWithout Controller

Store BXS8050-CI

Table Size: 80x100 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopInternal Controller; RS-485 / USB

Store BXS8050-CE

Table Size: 80x100 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; RS-485 / USB

Store BXS8050-CE-EC

Table Size: 80x100 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; EtherCAT

Store BXS8050-CE-EN

Table Size: 80x100 mmTravel Stroke: 50 mmGuiding: Linear ball cageClosed LoopExternal Controller; Ethernet

Store BXN5050-O

Table Size: 50x50 mmTravel Stroke: 50mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN5050-CI

Table Size: 50x50 mmTravel Stroke: 50mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN5050-CE

Table Size: 50x50 mmTravel Stroke: 50mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN5050-CE-EC

Table Size: 50x50 mmTravel Stroke: 50mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN5050-CE-EN

Table Size: 50x50 mmTravel Stroke: 50mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN5075-O

Table Size: 50x50 mmTravel Stroke: 75mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN5075-CI

Table Size: 50x50 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN5075-CE

Table Size: 50x50 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN5075-CE-EC

Table Size: 50x50 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN5075-CE-EN

Table Size: 50x50 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN50100-O

Table Size: 50x50 mmTravel Stroke: 100mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN50100-CI

Table Size: 50x50 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN50100-CE

Table Size: 50x50 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN50100-CE-EC

Table Size: 50x50 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN50100-CE-EN

Table Size: 50x50 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN50150-O

Table Size: 50x50 mmTravel Stroke: 150mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN50150-CI

Table Size: 50x50 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN50150-CE

Table Size: 50x50 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN50150-CE-EC

Table Size: 50x50 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN50150-CE-EN

Table Size: 50x50 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN50200-O

Table Size: 50x50 mmTravel Stroke: 200mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN50200-CI

Table Size: 50x50 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN50200-CE

Table Size: 50x50 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN50200-CE-EC

Table Size: 50x50 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN50200-CE-EN

Table Size: 50x50 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN6075-O

Table Size: 60x60mmTravel Stroke: 75mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN6075-CI

Table Size: 60x60mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN6075-CE

Table Size: 60x60mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN6075-CE-EC

Table Size: 60x60mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN6075-CE-EN

Table Size: 60x60mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN60100-O

Table Size: 60x60mmTravel Stroke: 100mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN60100-CI

Table Size: 60x60mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN60100-CE

Table Size: 60x60mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN60100-CE-EC

Table Size: 60x60mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN60100-CE-EN

Table Size: 60x60mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN60150-O

Table Size: 60x60mmTravel Stroke: 150mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN60150-CI

Table Size: 60x60mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN60150-CE

Table Size: 60x60mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN60150-CE-EC

Table Size: 60x60mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN60150-CE-EN

Table Size: 60x60 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN60200-O

Table Size: 60x60mmTravel Stroke: 200mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN60200-CI

Table Size: 60x60mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN60200-CE

Table Size: 60x60mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN60200-CE-EC

Table Size: 60x60mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN60200-CE-EN

Table Size: 60x60mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN60250-O

Table Size: 60x60mmTravel Stroke: 250mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN60250-CI

Table Size: 60x60mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN60250-CE

Table Size: 60x60mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN60250-CE-EC

Table Size: 60x60mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN60250-CE-EN

Table Size: 60x60mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN60300-O

Table Size: 60x60mmTravel Stroke: 300mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN60300-CI

Table Size: 60x60mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN60300-CE

Table Size: 60x60mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN60300-CE-EC

Table Size: 60x60mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN60300-CE-EN

Table Size: 60x60mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN8075-O

Table Size: 80x80 mmTravel Stroke: 75mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN8075-CI

Table Size: 80x80 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN8075-CE

Table Size: 80x80 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN8075-CE-EC

Table Size: 80x80 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN8075-CE-EN

Table Size: 80x80 mmTravel Stroke: 75mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN80100-O

Table Size: 80x80 mmTravel Stroke: 100mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN80100-CI

Table Size: 80x80 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN80100-CE

Table Size: 80x80 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN80100-CE-EC

Table Size: 80x80 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN80100-CE-EN

Table Size: 80x80 mmTravel Stroke: 100mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN80150-O

Table Size: 80x80 mmTravel Stroke: 150mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN80150-CI

Table Size: 80x80 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN80150-CE

Table Size: 80x80 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN80150-CE-EC

Table Size: 80x80 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN80150-CE-EN

Table Size: 80x80 mmTravel Stroke: 150mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN80200-O

Table Size: 80x80 mmTravel Stroke: 200mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN80200-CI

Table Size: 80x80 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN80200-CE

Table Size: 80x80 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN80200-CE-EC

Table Size: 80x80 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN80200-CE-EN

Table Size: 80x80 mmTravel Stroke: 200mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN80250-O

Table Size: 80x80 mmTravel Stroke: 250mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN80250-CI

Table Size: 80x80 mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN80250-CE

Table Size: 80x80 mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN80250-CE-EC

Table Size: 80x80 mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN80250-CE-EN

Table Size: 80x80 mmTravel Stroke: 250mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store BXN80300-O

Table Size: 80x80 mmTravel Stroke: 300mmGuiding: Recirculating linear ballOpen LoopWithout Controller

Store BXN80300-CI

Table Size: 80x80 mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopIntegrated Controller; RS-485 / USB

Store BXN80300-CE

Table Size: 80x80 mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; RS-485 / USB

Store BXN80300-CE-EC

Table Size: 80x80 mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; EtherCAT

Store BXN80300-CE-EN

Table Size: 80x80 mmTravel Stroke: 300mmGuiding: Recirculating linear ballClosed LoopExternal Controller; Ethernet

Store

Custom Made

Ihre Vision, unser Engineering – Lassen Sie uns etwas Starkes daraus schaffen

Bei GMT Europe wissen wir, dass jedes Projekt einzigartig ist und Produktanforderungen von Fall zu Fall spezieller sein können. Deshalb legen wir großen Wert auf individuelle Kundenbetreuung und einen maßgeschneiderten Service. Unser "Custom Made"-Ansatz ermöglicht es uns, diese speziellen Anforderungen zu ergründen und mit Ihnen gemeinsam Produkte zu anzupassen oder neu zu entwickeln, die den besonderen Bedürfnissen gerecht werden.

Von der Konzeption bis zur Umsetzung stehen wir persönlich an Ihrer Seite und bieten eine umfassende Beratung. Dabei denken wir auch gerne mal um die Ecke oder schaffen neue Maßstäbe. Unser erfahrenes Team kombiniert Fachwissen, Erfahrung und Leidenschaft, um Ihre Ideen zum Leben zu erwecken.

Questions?

We’d like to hear from you

If you have any questions about our product range or need assistance finding the right product, please feel free to contact Matthias, our Sales Director. He looks forward to hearing from you and will provide expert advice on our products, working with you to find the right solution for your needs.

Matthias

+49(0) 4488 - 761 746 300

sales@gmteurope.de